Modulus: Redefining the Future of Biopharma Manufacturing

At Sanofi, we don’t wait for the future, we design it. Meet Modulus, a first-of-its-kind, next-generation biotech manufacturing facility that is rewriting the rules of pharmaceutical production.

In today's complex global healthcare landscape, where our pipeline evolves rapidly and unforeseen health challenges emerge, Modulus stands at the forefront of innovation. This platform anticipates change and enables flexible, agile production to meet these dynamic challenges— representing a complete paradigm shift in biopharmaceutical manufacturing.

The Power of Modular Thinking

Imagine having thirty-four mini-factories at your fingertips, each one ready to pivot like pieces of a sophisticated LEGO platform—able to be combined, reshuffled, and/or upgraded easily, enabling fast, scalable, and adaptable manufacturing.

While traditional sites are locked into manufacturing one product—or one class of products—for months or years, Modulus can manufacture up to four different vaccines or biologics simultaneously andsignificantly reduces production changeover times between any pre-validated technology platforms to as little as one week, while the industry standard remains several months.

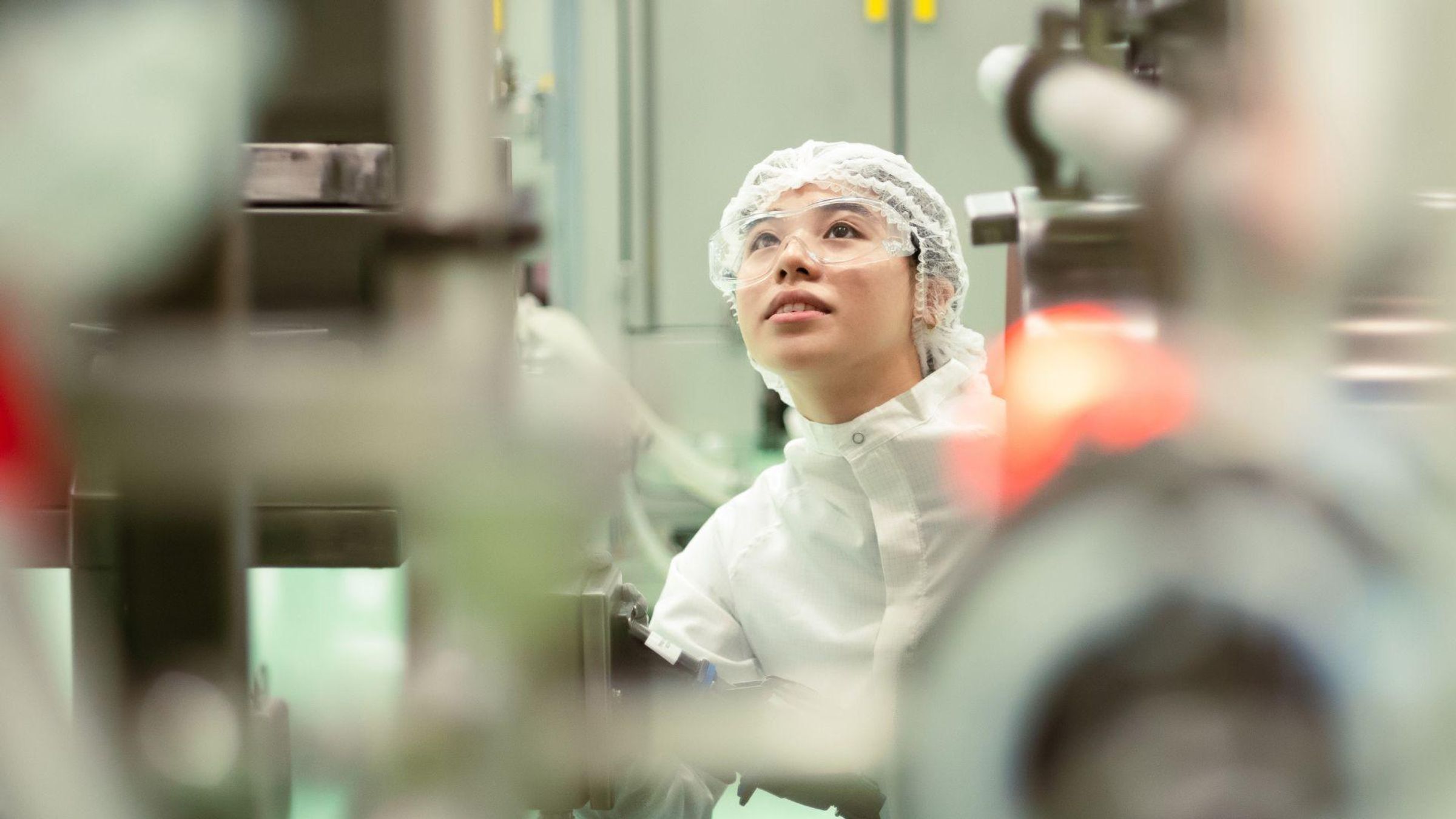

Technicians in the production area at Modulus in Neuville-sur-Saône, France

Whether we need to produce one vaccine in large volumes or four different vaccines or biologics at once—and many combinations in between—we can adapt our production "menu" practically on-demand.

Modulus represents a win-win-win innovation in the field of biopharma manufacturing. More than just a factory, it redefines healthcare delivery with flexibility and speed, enabling us to meet the evolution of our pipeline, as well as adapt to the pressing needs of public health—all while delivering on our sustainability commitments.

Brendan O'Callaghan

Executive Vice President, Manufacturing & Supply

Digital Intelligence at Every Level

What sets Modulus apart is its digital DNA. Advanced AI systems coordinate autonomous guided vehicles to improve the building’s internal logistics, while others support quality control. At the same time, real-time sensor data collected throughout the line and process enables us to real-time analyze equipment data, forecast maintenance needs, and accelerate quality inspections. This allows us to anticipate our process needs and move towards process deviations prediction and beyond process optimization unlike ever before, which further reinforces our production capacities and reliability.

Smart by Design, Sustainable by Choice

Every aspect of Modulus embeds advanced AI, digitalization, and automation throughout the site. But intelligence without responsibility isn't progress—that's why we also champion reduced environmental footprints and energy efficiency on each Modulus site. Our facility in Neuville-sur-Saône has earned LEED Gold certification, (Leadership in Energy and Environmental Design) a globally recognized standard for green building and sustainable design.

The People Behind the Machines

Behind the Modulus sites in Neuville and Singapore, are our people who dared to reimagine manufacturing from the ground up. Their big ideas and commitment to patients have transformed concept into reality. All of the innovations embedded in these unique manufacturing hubs serve a singular purpose—getting life-changing vaccines and treatments to people, faster than ever before.

Explore More

Manufacturing & Supply

How Eco-Design Makes for a Healthier and More Sustainable World