AI Across the R&D Value Chain: Manufacturing - Digital Labs and Self-Sharpening Tools

From preclinical development to commercial manufacturing, a new generation of AI software is accelerating how medicines are made.

In Part 3 of our 4-part series on how AI is transforming R&D, we look at how digital tools are reshaping the development journey: accelerating production, improving quality, and empowering scientists to focus on innovation.

In his Cambridge, MA lab, Shawn Walker, Global Head of Synthetics Chemistry, Manufacturing and Controls (CMC) Development, introduces a key member of his team. “Solutron,” a multi-jointed collection of robotic arms and cables designed by Sanofi scientists, is whirring away, creating a chemical solution from a collection of ingredients. “If it’s a repetitive task,” says Walker, “we’ll leverage robotics to do it.”

Solutron is just one part of Walker’s larger vision, where AI agents augment a range of scientific efforts from analyzing data to making decisions about experiments, and automated labs are powered by robotics.

Our ambition is to integrate human-AI collaboration at every stage of process and product design.

Shawn Walker

Global Head of Synthetics Chemistry, Manufacturing and Controls (CMC) Development

CMC Development: Wet Lab Meets Dry Digital

Developing the production process for a new medicine is a time-consuming journey. Expert insights are coupled with precise tools to conduct focused experiments, grappling with the detailed physical properties of both the new medicine and all the raw materials along the way. It’s a complicated dance of ingredients and instruments, all demanding exquisite precision. Now, AI and robotics are changing the rhythm of this journey, bringing unprecedented digital precision and speed to the craft of making medicines.

A molecule’s solubility – how much can be dissolved in a given liquid – is a critical physical property that impacts multiple steps of manufacturing, from removing impurities to how much of a final active ingredient is in the body. Optimizing that solubility adds additional layers of complexity. All of this requires thousands of measurements and refinements along a molecule’s journey to becoming a medicine. Across a portfolio of new drug candidates, it’s a big task – and manually performing all these solubility experiments would be incredibly time- and resource-intensive.

Solutron has taken over this type of experimental work, accelerating process development with precision and reproducibility – methodically generating data that feeds back into AI models, enabling continuous learning. Walker explains the current evolution: “By shifting repetitive, manual tasks to digital and robotics platforms like Solutron, we’re empowering scientists to work at the leading edge of innovation – doing things we can’t automate.”

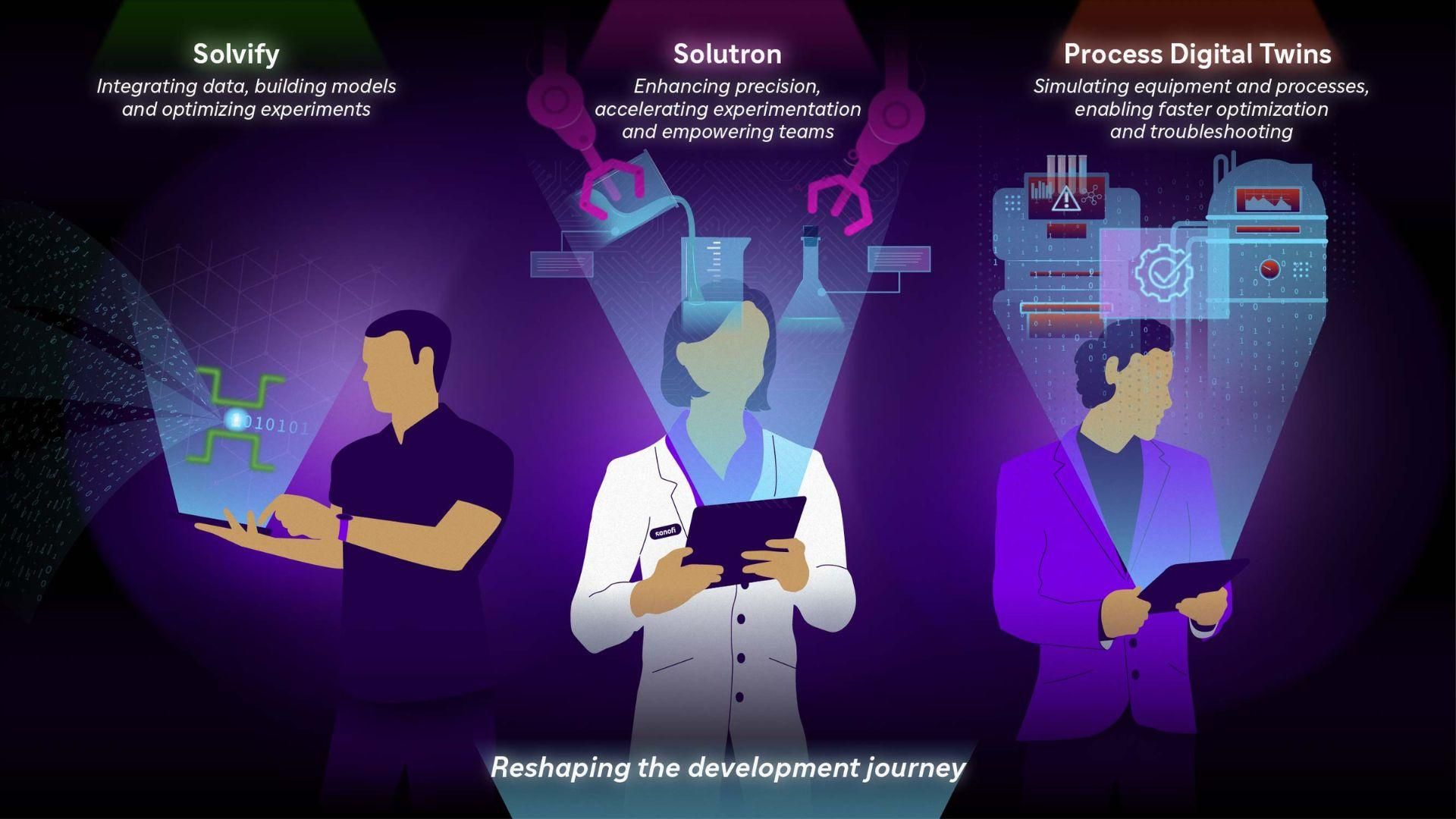

A New Generation of Tools

Automated solubility experiments are just part of what’s evolving in Walker’s domain of CMC Development. AI and machine learning (ML) initiatives have produced digital tools that are accelerating nearly every step of process development. Before physical experiments happen in the lab, the “Solvify” solubility prediction tool integrates a vast array of public and Sanofi-owned chemical data, creating models and narrowing the focus, determining what physical experiments Solutron conducts. “Our prediction software tells us where we should start,” explains Walker of the AI-enabled journey. “Solutron then gives us new, real data, so we can update our models and learn even faster. These are self-sharpening tools.” It’s a more efficient approach that enables teams to conduct the physical experiments that matter most.

Together, this new generation of AI and robotics illustrates a broader shift: scientists and machines as partners in drug development, with each cycle of experimentation refining the next.

More Data, (No) More Problems

More experiments – real and virtual – means more data to analyze. Novel software is changing how we analyze and interpret experiments, too. Sanofi’s Kinetic AI platform illuminates results from chemical reactions – helping to understand complex reaction mechanisms, what’s rate-limiting, what types of impurities could be formed, and more. Meanwhile, Large Language Models (LLMs) are used to simplify the connectivity between the scientists and the robots, design new experiments and navigate the data ecosystem more easily.

From Laboratory to Manufacturing Plant

Creating a new molecule is just the beginning of its journey to becoming a medicine. Bringing that new molecule from the lab to clinical trials requires designing and scaling up the manufacturing process. Just as a chef would prepare a meal for four differently than they would prepare a meal for hundreds, scale-up is much more complicated than taking the initial recipe and simply increasing the amounts of raw ingredients.

By leveraging AI and modeling solutions before we start large-scale manufacturing, we ensure that every process we develop is robust and optimized.

Christian Airiau

Global Head of CMC Data Sciences and Global CMC Development

Airiau and his team are focused on designing the most efficient processes to enable larger-scale manufacturing, ensuring a medicine can be produced safely, consistently and efficiently.

New AI tools are accelerating this phase of development, too. The digital models used in the process development phase to learn how a molecule behaves, are different from the models used to control larger-scale processes during manufacturing. The insights, however, are every bit as vital.

Digital Labs Optimizing Virtual Processes

Just as “digital twins” are changing clinical trials, “process digital twins” are also revolutionizing Sanofi’s manufacturing. In clinical trials, digital twin experiments use vast amounts of patient data in simulations to evaluate a medicine based on a range of human attributes. Airiau’s team is applying a similar approach to process development.

Process digital twins – models of equipment and biological or chemical processes across manufacturing steps – enable teams to simulate the production of a molecule. These twins can efficiently evaluate unlimited numbers of conditions, reducing the number of real-world experiments. They can also give early signals that a process needs optimization. From a virtual environment comes unprecedented control. A digital revolution is accelerating production, with the goals of maximizing productivity and product quality.

Integrated AI, robotics & digital twins: Solvify predicts, Solutron experiments, twins simulate to accelerate drug R&D & manufacturing.

Towards Patient Use: Manufacturing Scale-up

As a medicine moves towards approval, the shift to commercial-scale manufacturing needs to be a smooth transition.

Preparation for this scale of manufacturing starts early because it’s critical to master the process as soon as possible, to ensure we are fully ready for manufacturing and control.

Olivier Moureau

Head of Process Data Science and Digital Transformation for Manufacturing Science Analytics Technology (MSAT)

As technology is transferred between teams, AI and digital tools are playing transformative roles. At this phase, experts are focused on process monitoring and control to ensure quality, maximizing the number of doses that can be produced, and reacting quickly if troubleshooting is needed.

Generative AI tools are used to create reports, enabling better and faster decision-making. ML tools are used to identify optimal production conditions, increasing productivity. Process digital twins enable virtual experimentation at scale, reducing expensive and time-consuming real-world data gathering, and accelerating timelines. Models are developed to better understand things like product stability, which impact how long a medicine can be on a shelf or in a refrigerator prior to being administered to a patient. Generative AI agents gather data, enabling collaboration and knowledge sharing within the organization and beyond.

Digital Models Transforming Process Optimization

Producing medicines quickly and correctly at scale, while maintaining high quality standards, can be challenging in any large manufacturing network. Including external manufacturing partners increases the difficulty, but shows the importance of our new digital environment.

Recently, as a partner company was preparing to manufacture its first batches of a Sanofi product, the process needed urgent troubleshooting. Responding in real-time, digital process twins were used to find answers.

Rather than conducting physical experiments, a Sanofi scientist fed the partner’s data into a digital model of the process. The model was leveraged to identify the root cause of the problems seen at the production site, test solutions, and refine the settings on the partner’s equipment. Doing physical experiments to replicate the issue and identify solutions could have taken months. But digital approaches enabled the scientist to find a fix in just a few days.

We are now using digital tools to solve problems at scale in real-time. That was just not possible in previous years.

Olivier Moureau

Head of Process Data Science and Digital Transformation for Manufacturing Science Analytics Technology (MSAT)

Data Availability and Governance as the Foundation for Transformation

Across a new molecule’s journey to patients, data is a critical asset. Consistent, reliable information must be ensured from early CMC through manufacturing, as it is the foundation for all AI and modeling activities. To integrate more AI and digital twins into manufacturing, cross functional teams aim to reduce data fragmentation across diverse systems, equipment and processes. Accessing all that data, in real time and across a large network of locations, is key to success.

These efforts are not just about modernizing labs and manufacturing. This digital, AI-powered world is about building a smarter, more connected ecosystem that can bring innovative and high-quality medicines to patients faster. With two decades of experience in manufacturing, Olivier is excited by the journey – and the big changes – ahead.

-----

As AI continues to reshape every link of the R&D value chain, we turn to the next frontier: using AI to inform smarter and faster portfolio decisions. Stay tuned for the fourth and final installment of our AI in R&D series, where we explore how data, modeling, and machine intelligence are helping scientists and leaders decide which ideas to pursue, and how to bring them to patients sooner.

For more in the ‘AI Across the R&D Value Chain’ series, read Part 1: Drug Discovery, and Part 2: Clinical Development.