About Manufacturing & Supply at Sanofi

Sanofi manufactures 2 billion doses of medicines and vaccines annually across 37 global production sites, transforming scientific discoveries into treatments that reach patients worldwide.

Our pharmaceutical manufacturing & supply network produces small molecule drugs, complex biologics, vaccines, and medical devices using AI-powered systems, continuous biologics production technologies, modular facilities, and sustainable practices.

This approach ensures robust GMP (Good Manufacturing Practices) compliance and quality assurance, so every medicine meets the highest quality standards while reaching patients faster and more reliably.

Our Pharmaceutical Manufacturing & Supply in Figures*

2bn

doses of medicines and vaccines delivered annually to patients across the world**

>€1bn

invested annually in modernizing and digitizing our Manufacturing & Supply network

37

sites backed by more than 28,000 employees and enabled by advanced technology platforms

*Figures at end of 2025

** Includes in-house and outsourced manufacturing

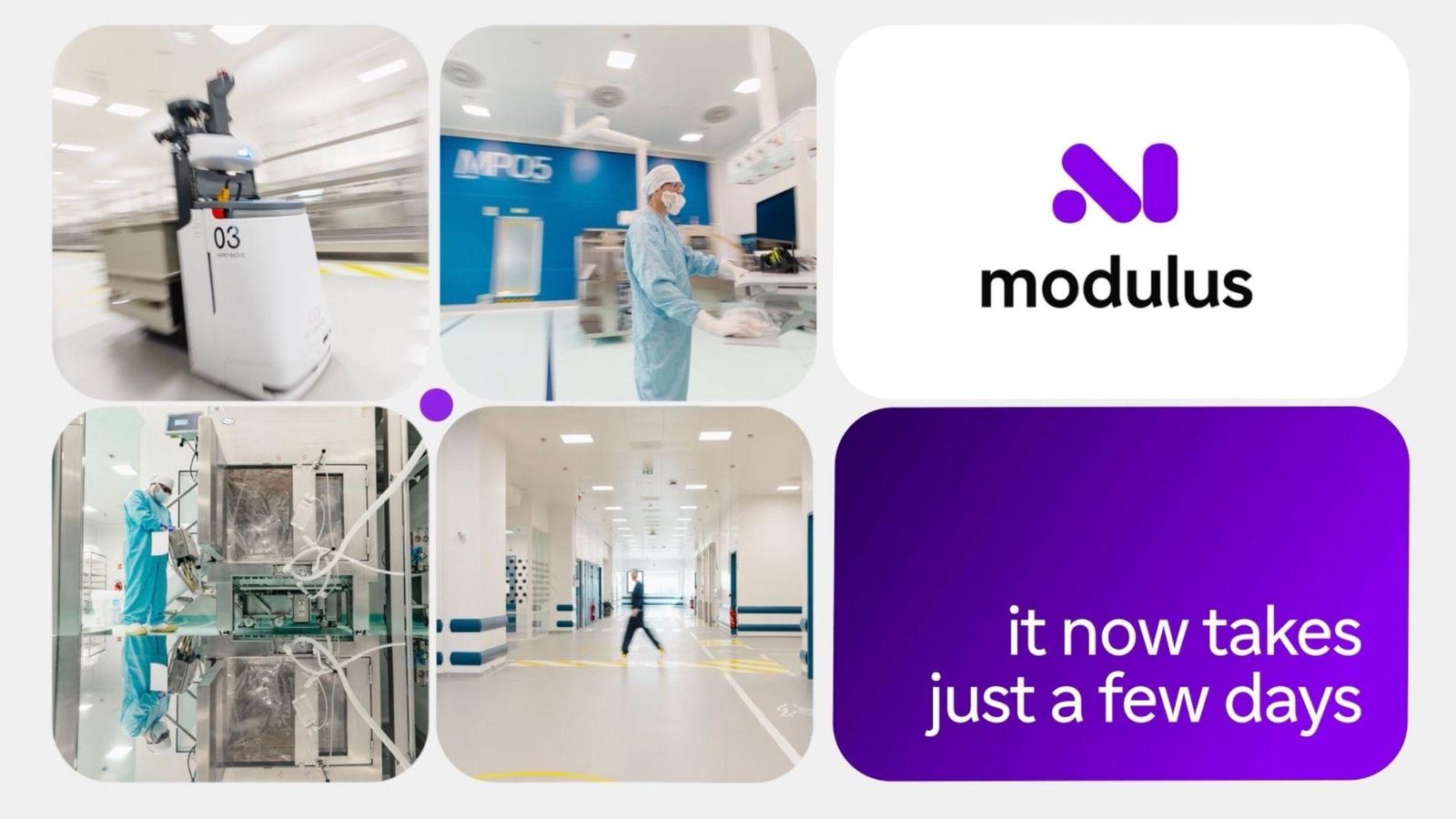

What Is Modular Biomanufacturing? The Future of Pharmaceutical Production

Patients can’t wait, so neither do we. With more than €1 billion invested annually in capacity expansion, digital manufacturing, and manufacturing modernization (including continuous biologics production and advanced vaccines manufacturing facilities), we’re making manufacturing faster, more flexible, and more resilient than ever before.

Modulus, our modular biomanufacturing platform, leverages continuous biologics production technology, modular facilities, and automation in production to allow Sanofi to produce up to four different vaccines or biologics simultaneously. With a plug-and-produce design, we can switch between technology platforms and products in days instead of months, while maintaining pharmaceutical quality standards. This innovation was recognized by TIME Magazine as one of 2025’s Best Inventions in Medical and Healthcare.

How AI and Digital Technology Transform Pharmaceutical Manufacturing

We combine deep expertise with advanced analytics, AI in manufacturing, and cutting-edge technology to sharpen performance at every level. By simplifying, standardizing, and digitizing core processes, we’re creating a connected, resilient manufacturing network that delivers manufacturing excellence and quality assurance with confidence.

We’ve built scalable digital systems that unify information across sites, powering smarter decisions and more predictable outcomes across our global supply chain. Our pharmaceutical manufacturing capabilities leverage advanced analytics to improve asset utilization, boost yields, and enhance supply reliability — helping us achieve operational excellence and deliver the right medicine, at the right time, to every patient who depends on it.

From next-gen analytics to performance dashboards and AI in manufacturing, we’re transforming our network into a smart factory and a world-class manufacturing engine. By embedding manufacturing excellence and operational excellence in every process, we ensure our operations are precise, efficient, and always improving.

How Manufacturing Excellence Applies Formula 1 Precision to Pharmaceutical Production

Pharmaceutical manufacturing excellence at Sanofi means reducing changeover times by 40%, boosting asset efficiency by 30%, and strengthening forecasting accuracy through advanced analytics and AI-powered systems.

We apply Formula 1 precision principles from our McLaren Racing partnership to optimize every stage of biopharmaceutical production, embedding operational excellence and quality assurance to ensure consistent quality across every batch, every site, every time.

How Sanofi Ensures Sustainable Pharmaceutical Manufacturing and Equitable Global Health Access

Our focus goes beyond production lines; it starts and ends with people. We design solutions with patients in mind, from user-friendly devices to eco-designed medicines and vaccines, and sustainable packaging that improves treatment adherence and accessibility, all while reducing our environmental footprint.

We work to bring essential medicines to underserved communities worldwide, expanding access where it’s needed most. And we’re committed to a sustainable supply chain and manufacturing, adopting an eco-design approach for our medicines and vaccines, while driving carbon footprint reduction through ambitious targets, smarter design, and responsible manufacturing practices that protect the planet for generations to come.

The People Behind Pharmaceutical Manufacturing & Supply Excellence

Discover the innovative stories of the people redefining the future of biopharma manufacturing every day.